Overview

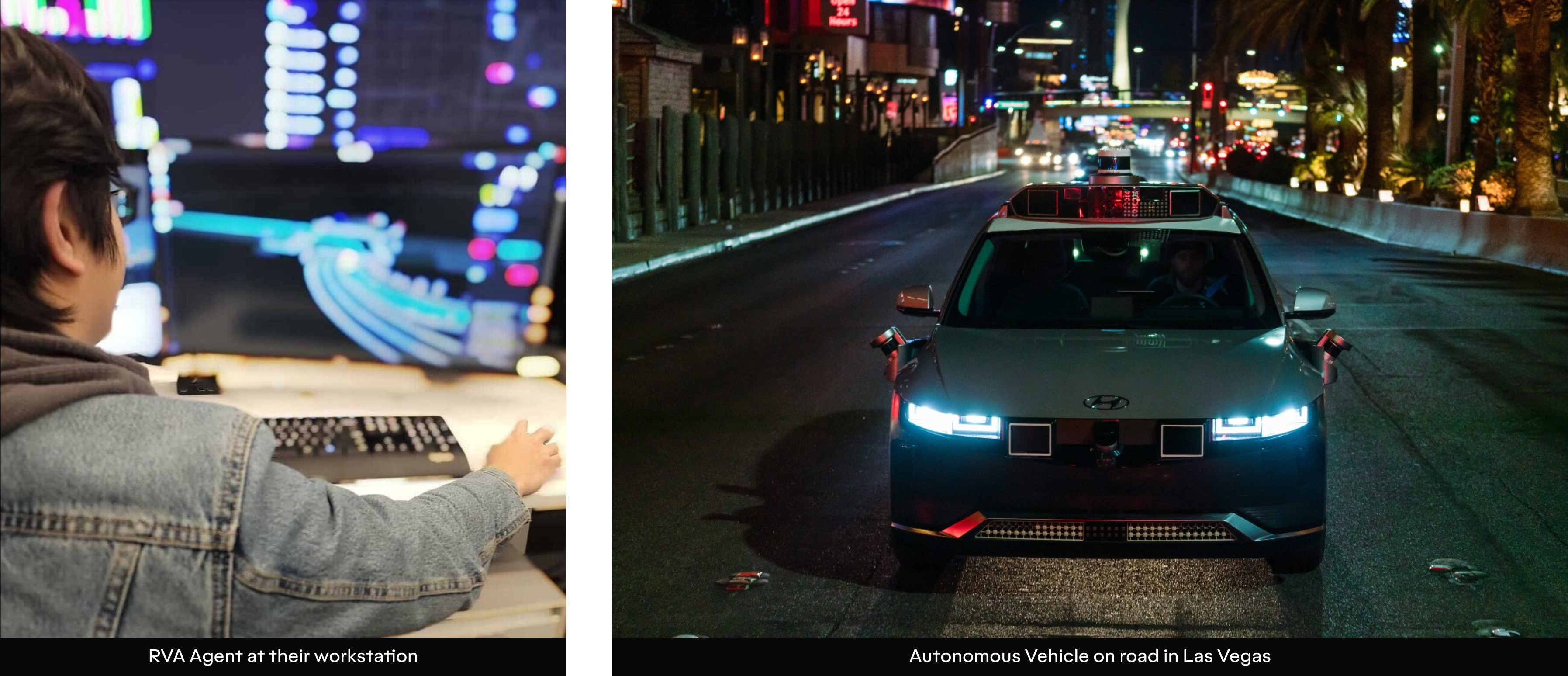

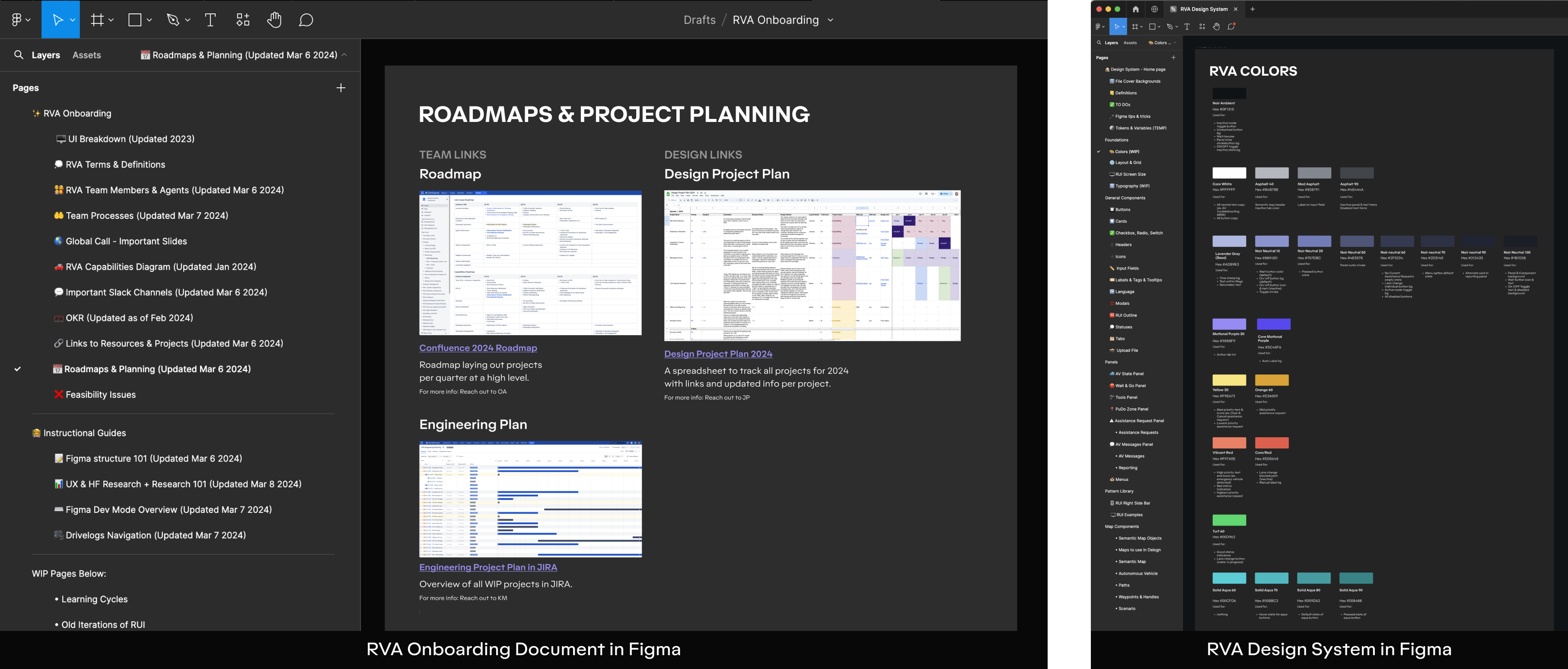

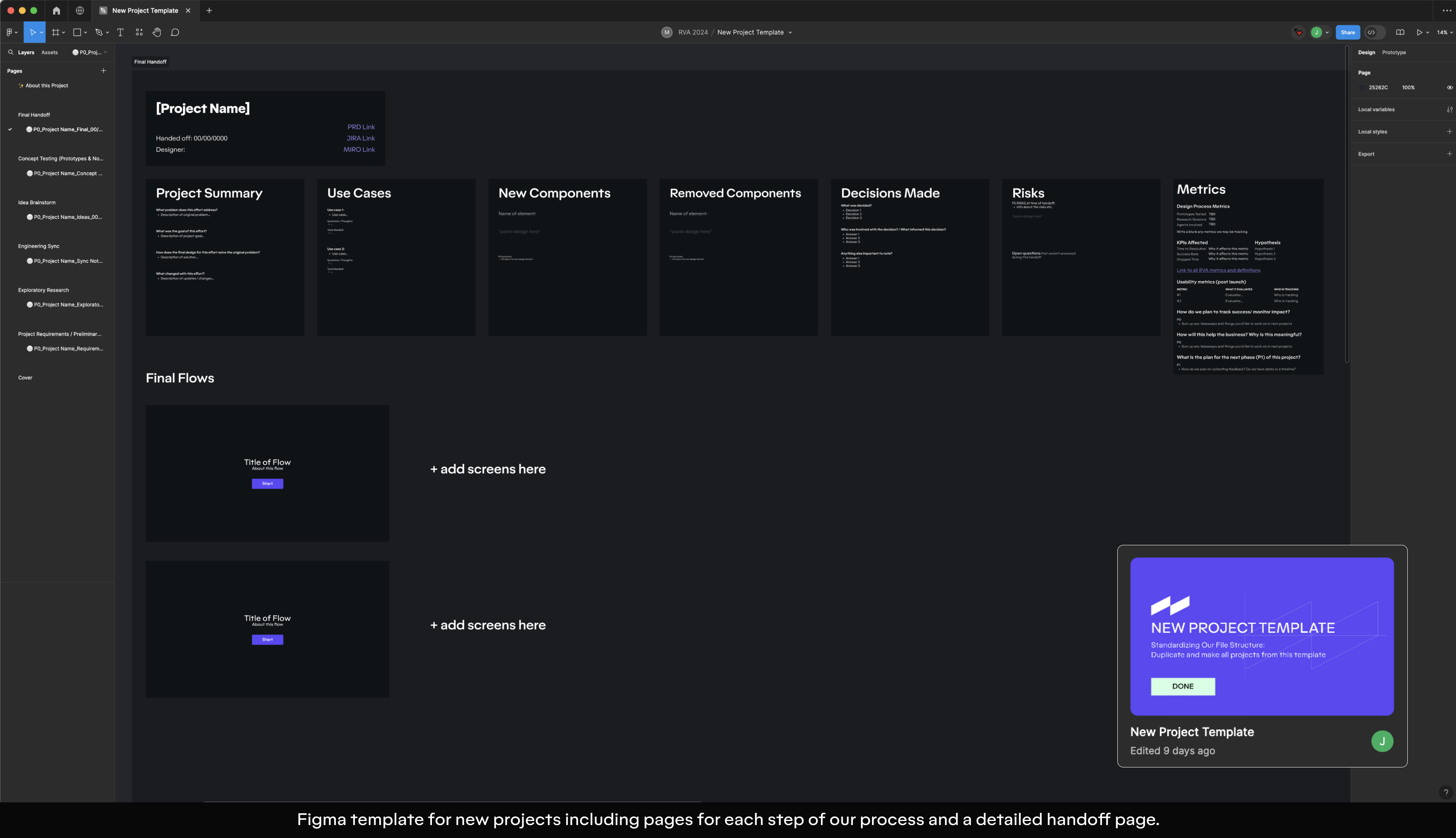

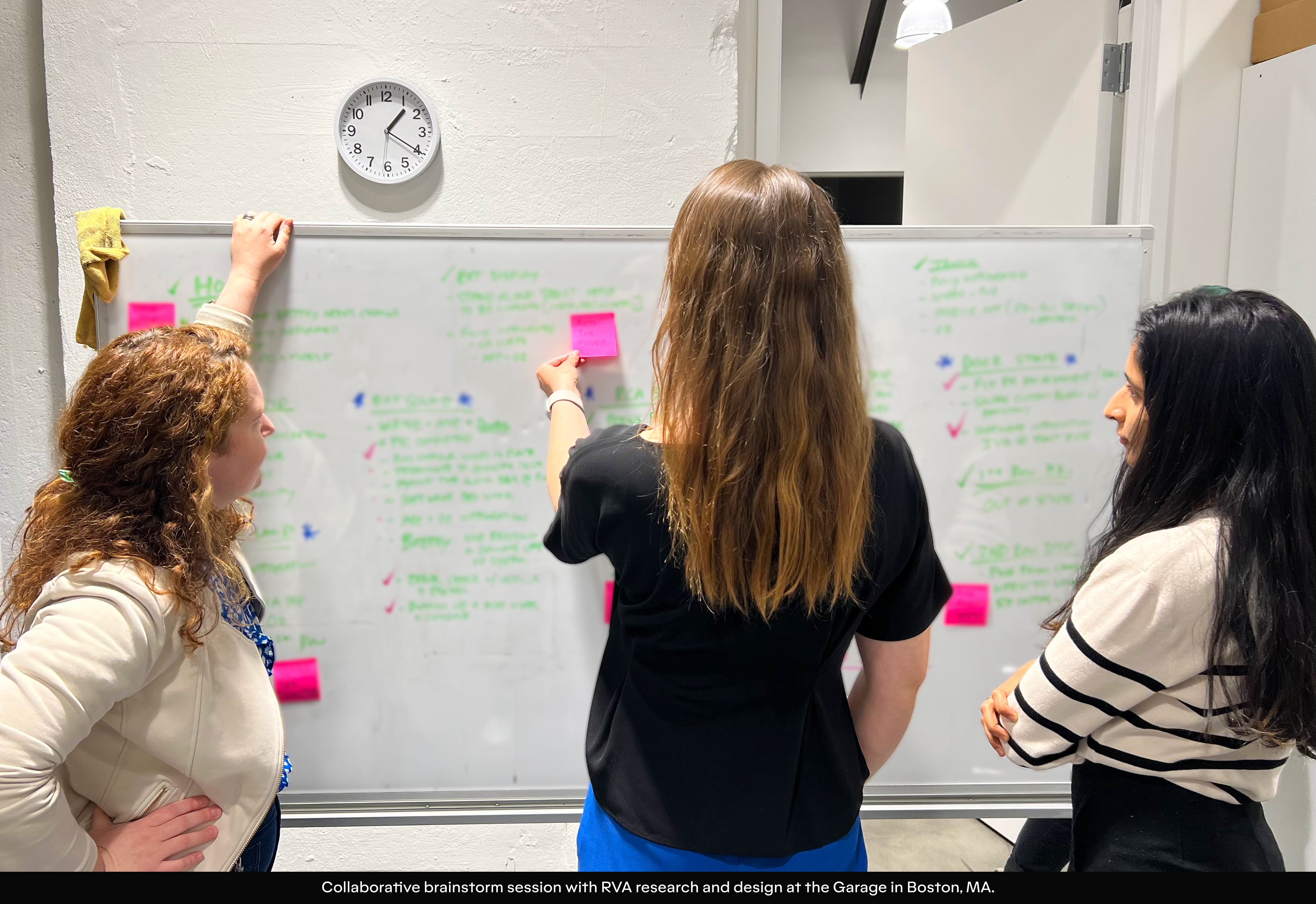

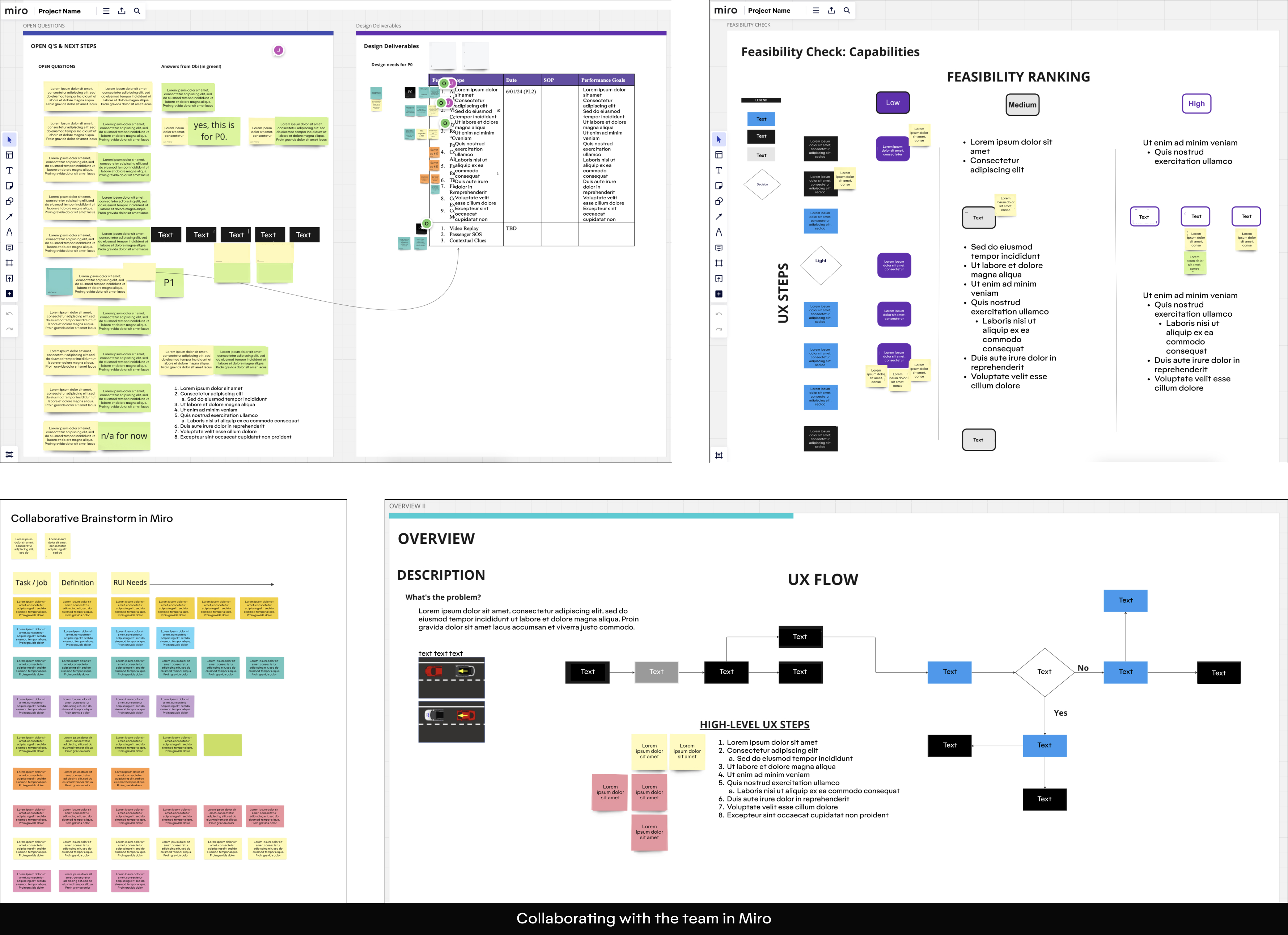

Remote operators (agents) worked from dual monitor workstations in the Las Vegas Command Center to assist autonomous vehicles in challenging scenarios. As the design lead, I drove the creation of intuitive tools while simultaneously improving team processes and building essential infrastructure.